RODUCT NAME :

alloy structure steel

STANDARD:

GB/T3077-1999 EN10083-1 EN10083-3 ISO 683-1

GRADE COMPARISION:

|

GB |

ГОСТ |

ASTM |

BS |

JIS |

DIN |

|

20Mn2 |

20Г2 |

1320,1321 |

150M19 |

SMn420 |

20Mn5 |

ULTRASONIC STANDARD:

GB/T6402-2008 / SEP921-84. ASTM A388

CHEMICAL COMPOSITION:

|

C |

Si |

Mn |

P≤ |

S≤ |

Cr |

|

0.16/0.22 |

0.15/0.40 |

1.20/1.60 |

0.035 |

0.035 |

≤0.29 |

HEAT TREATMENT SPECIFICATION & MECHANICAL PROPERTIES:

Have moderate strength , while cold deformation plasticity higher . Used in gear ,small shaft , piston pin , cross melt etc in automobile and tractor .

Tensile strength ≥785MPa

Yeild strenght ≥590MPa

Enlongation ≥10%

Reduction of area ≥40%

Impact ≥47Aku2/J

Hardness ≤187HB

Temperature temperature :℃ 220 , coolant : water , air . Quenching temperature 850.

DELIVERY CONDITION :

DIMENSION : mm

|

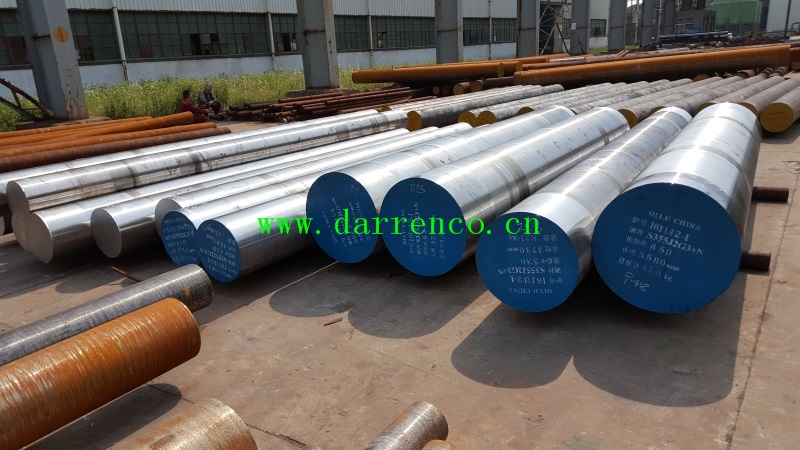

ROUND STEEL BAR |

COIL ROD |

WIRE |

SQUARE/ FLAT |

|

FORGED BAR |

ROLLED BAR |

HOT ROLLED |

COLD DRAW |

FORGED |

ROLLED |

|

80-650 |

16-250 |

∮5.5-20 |

∮0.2-13 |

120-800×120-800 |

5-38×44-150 10-90×60-305 |

APPLIED RANGE:

REMARK:

Above listed parameters and sepcification only for reference . Specific parameters according to standard. Requirments

beyond standard will be negotiated by both sides

.

Delivery state:annealed, spheroidal annealed, quenched & tempered ,bright bar, cold-drawn, etc.

Listed specifications are only typical grades; products of required specifications can be developed/produced as per international,

Chinese or industry standards, or

based on agreements with customers.