PRODUCT NAME :

alloy structure steel

STANDARD:

GB/T3077-1999 EN10083-1 EN10083-3 ISO 683-1

GRADE COMPARISION:

|

GB |

ГОСТ |

BS |

JIS |

NF |

DIN |

|

38CrMoAl |

38XMIOA |

905M39 |

SACM645 |

40CAD6.12 |

41CrAlMo07 |

ULTRASONIC STANDARD:

GB/T6402-2008 / SEP921-84. ASTM A388

CHEMICAL COMPOSITION:

|

C |

Si |

Mn |

P≤ |

S≤ |

Cr |

Mo |

Al |

|

0.35/0.42 |

0.20/0.45 |

0.30/0.60 |

0.035 |

0.035 |

1.35/1.65 |

0.15/0.25 |

0.70/1.10 |

HEAT TREATMENT SPECIFICATION & MECHANICAL PROPERTIES:

Quenching temperature (℃):940

Tensile strength σb (MPa):≥980(100)

Yeild strength σs (MPa):≥835(85)

elongation δ5 (%):≥ 14

Reduction area ψ (%):≥50

Impact Akv (J):≥71

Hardness :≤229

DELIVERY CONDITION :

normalized ,annealed, black surface ,rough machined or quenched & tempered , should be indicated in contract .

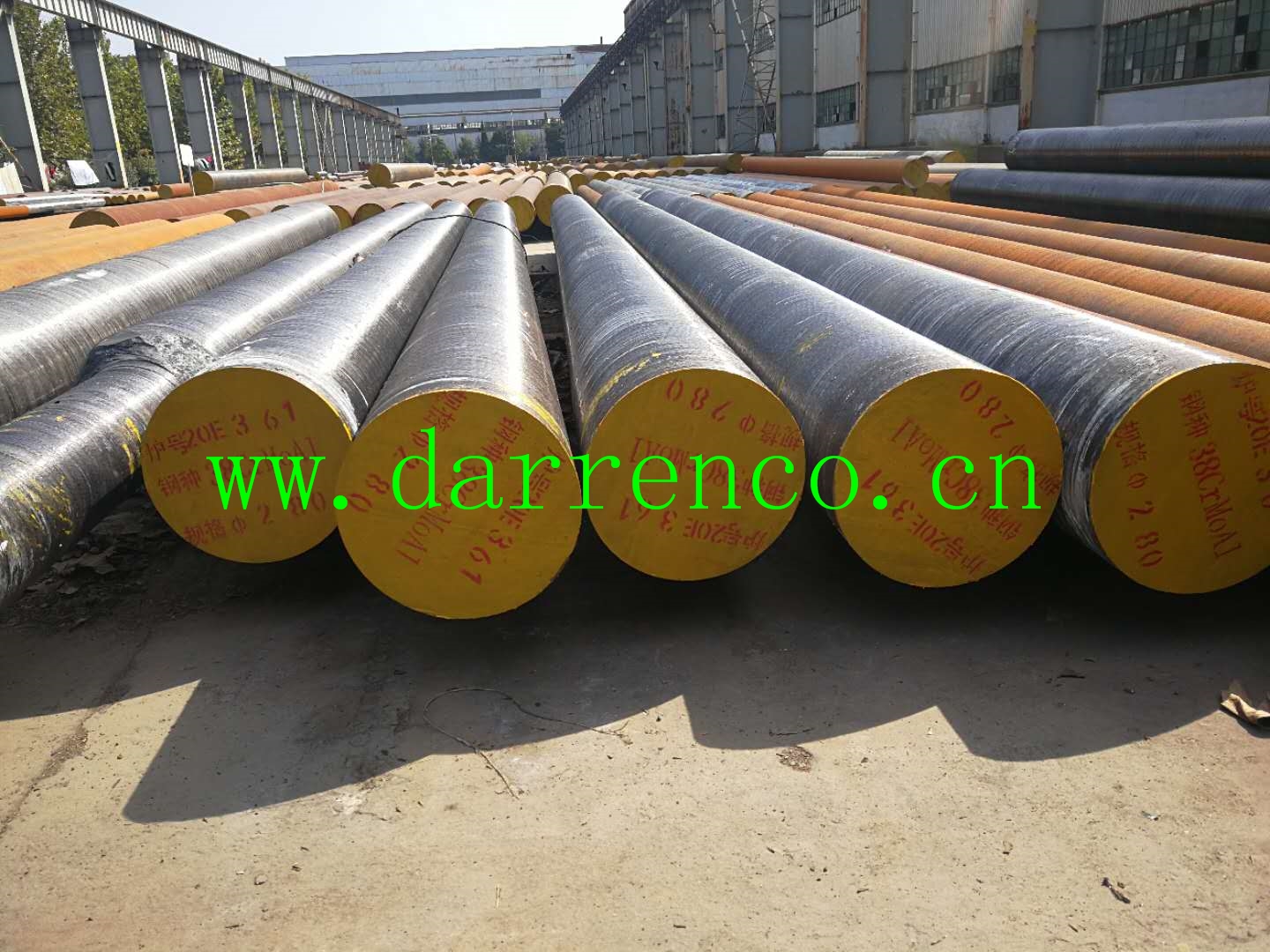

DIMENSION : mm

|

ROUND STEEL BAR |

COIL ROD |

WIRE |

SQUARE/ FLAT |

|

FORGED BAR |

ROLLED BAR |

HOT ROLLED |

COLD DRAW |

FORGED |

ROLLED |

|

80-650 |

16-250 |

∮5.5-20 |

∮0.2-13 |

120-800×120-800 |

5-38×44-150 10-90×60-305 |

length : forged bar free length 4-5.8M,rolled bar 5.8M. for customers special requirment, the bar length can do 20 meters long.

APPLIED RANGE:

Have very high nitrogenization performance and machinical perproties . Good heat resistance and stain resistance . Mostly used

for make all kinds of not large size nitrogenization parts which have high fatigue strength ,high wearing feature , demension accurate

after heat treatment , higher strength . Such as cylinder sleeve , socket sleeve , bottom cap , piston bolt , principal axis of precision

grinder, pricipal axis of lathe, boring bar , precision lead screw , gear ,worm ,high pressure valve , valve rod ,roller , some wear parts

of plastic extrusion .

REMARK:

Above listed parameters and sepcification only for reference . Specific parameters according to standard. Requirments beyond standard

will be negotiated by both sides.

Delivery state:annealed, spheroidal annealed, quenched & tempered ,bright bar, cold-drawn, etc.

Listed specifications are only typical grades; products of required specifications can be developed/produced as per international, Chinese

or industry standards,or based on agreements with customers.